In 19th-century California, not only ice, but even sources of naturally cold water, were probably unavailable to brewers. California brewers were forced to use lager yeast at higher ale temperatures.

Final flavors of beer are influenced by the strain of yeast and the fermentation temperature. Lager yeast is best used at temperatures from 48 to 58 °F (9 to 14 °C). Ale yeast is best used at temperatures from 55 to 75 °F (13 to 24 °C). Fermentation by ale yeasts produces a beer that has a distinctive ale flavor. Steam Beer uses bottom fermenting lager yeasts at ale temperatures, which results in a very distinctive flavor profile that includes both ale and lager characteristics.

The recipe that I based my brew on came from this blog, Steam Beer. The actual ingredients that I used were:

- 1.7 kg Coopers Real Ale beer kit

- 2 lb Briess Pilsen Dry Malt

- 4 oz Dark Crystal Malt Grain

- 1 oz US Northern Brewer Leaf Hops

- 23 g S-23 Lager Yeast (2x 11.5g)

The day before I actually made the beer I steeped the 4 ounces of crushed dark crystal grain in 3 quart saucepan with 2 quarts of cold water using cheese cloth. This saucepan was covered and stored in a refrigerator overnight.

The next day I removed the grain from the liquid of the pan and mixed in a 1/2 pound of the Briess pilsen dry malt extract. I brought the mixture up to a boil. Once it was boiling I added the ounce of Northern Brewer leaf hops and boiled for 10 minutes. If you are using this method, watch for a boil over as it can get quite messy.

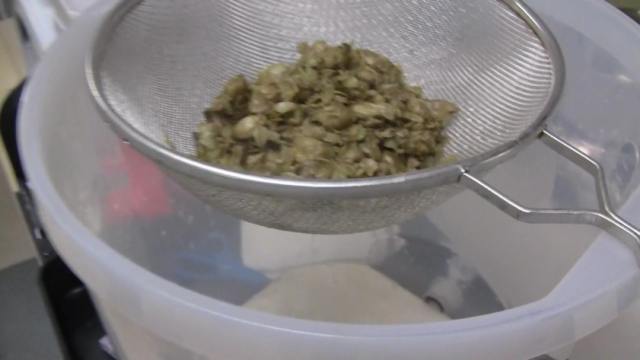

Remove pot from heat and place in a sink of cold water to get the temperature down. While waiting for the liquid to chill, I added the remaining Briess pilsen dry malt extract to my sanitized fermenter. I then added 2 liters of hot water to the fermenter. I immediately picked the fermenter to dissolve the dry malt extract (This method works great as dry malt extract is extremely hygroscopic and can get clumpy). I then strained the chilled grain/hop mixture into the fermenter. and mixed in the Real Ale brew can.

I then top the fermenter up to the 23 liter mark with cold filtered water and stirred vigorously. When the temperature was at 18 C I added the 2 sachets of Saflager yeast.

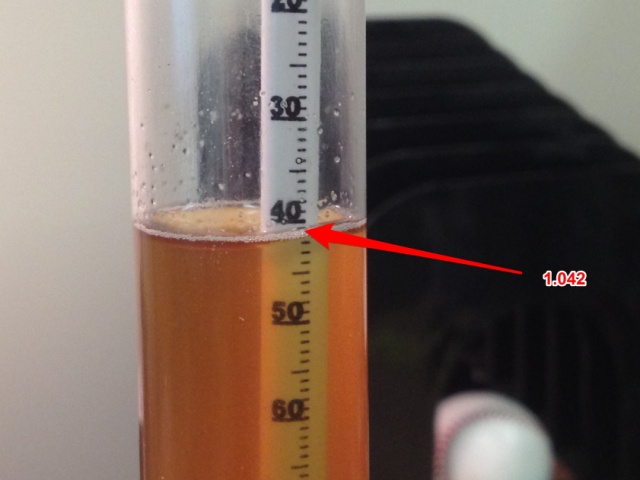

I took a sample of the beer and measured the specific gravity using a hydrometer. The original gravity reading was 1.042 which is lower than I wanted. I probably should have used another pound of dry malt extract.

I checked on my fermenter yesterday morning and was delighted to see a nice layer of krausen. All is proceeding nicely. The temperature on the fermenter says 16 C.

For a video demonstration of my brew day, you can watch it on Youtube here.